BUSINESS SOLUTION

Manufacturing Traceability System

A solution to enhance the traceability of manufacturing processes to monitor production lines in real-time using RFID/Barcoding and improved data capture and to provide electronic management of production orders

Features

Features

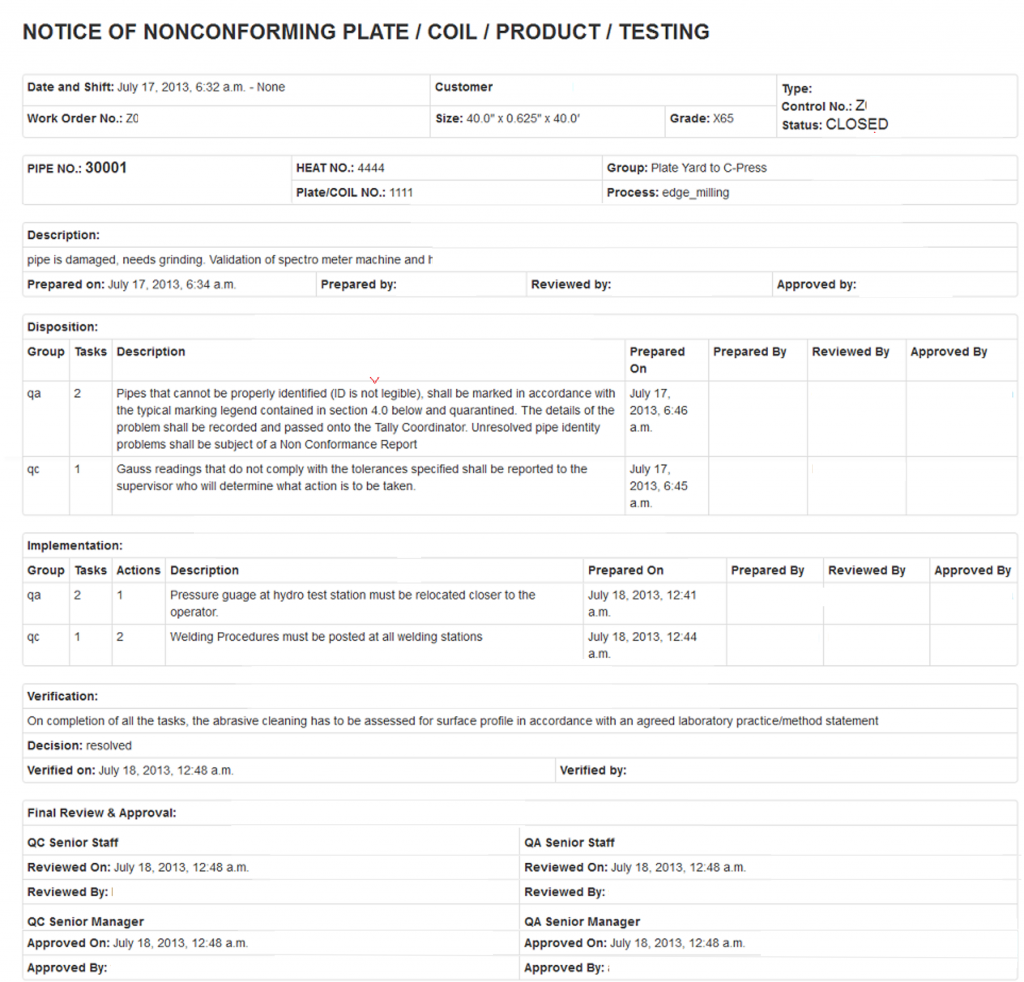

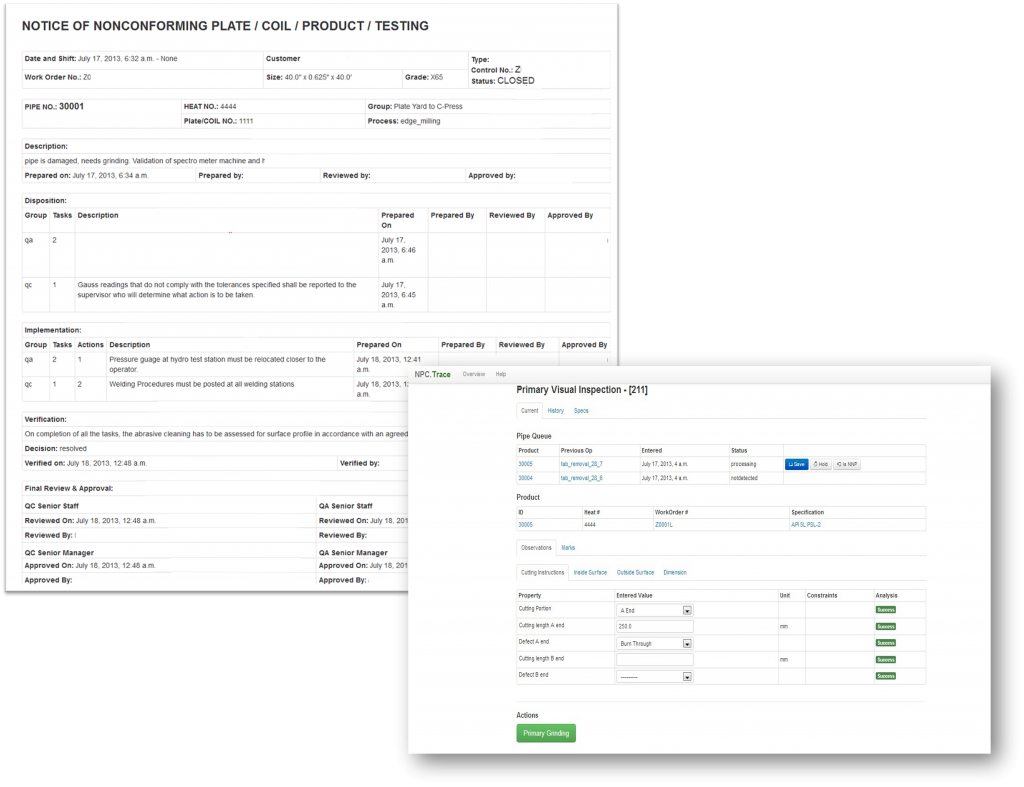

Provides complete visibility into the process of manufacturing from order to delivery. Comprehensive data capture to track the operations performed on the raw material as it transforms into a finished product, including but not limited to defects, inspections, repairs, non-destructive testing, operators, qualification of operators by tracking certifications and expirations, etc.

A complex rule-based workflow engine responsible for routing the raw material through different upstream and downstream processes. Enforces repairs and inspection, when required without the operator making a manual decision.

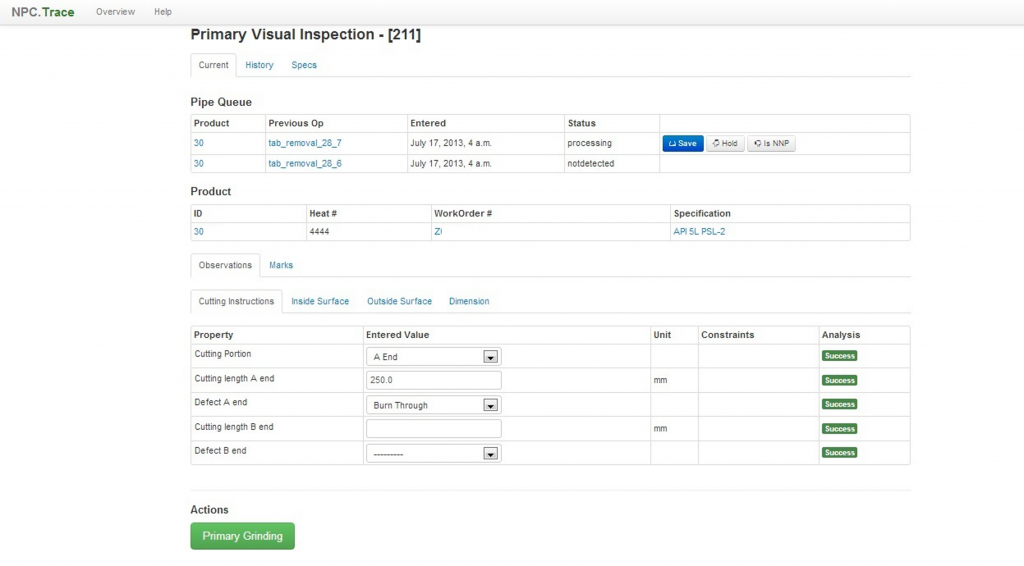

Checks in real-time the observables encoded against the specifications encoded in the work order based on the client's requirements and standard industry rules and guidelines.

An automated contact-less detection of the product as it arrives at a station for processing in the manufacturing plant.

A rugged handheld unit, heavily customized, to assist the operators in the manufacturing plant by performing several operations. The handheld unit acts as a fallback for detecting where a fixed RFID-based detection is not possible due to structural constraints. Provides quick information about the product being manufactured by performing a quick scan of RFID or the barcode tag.

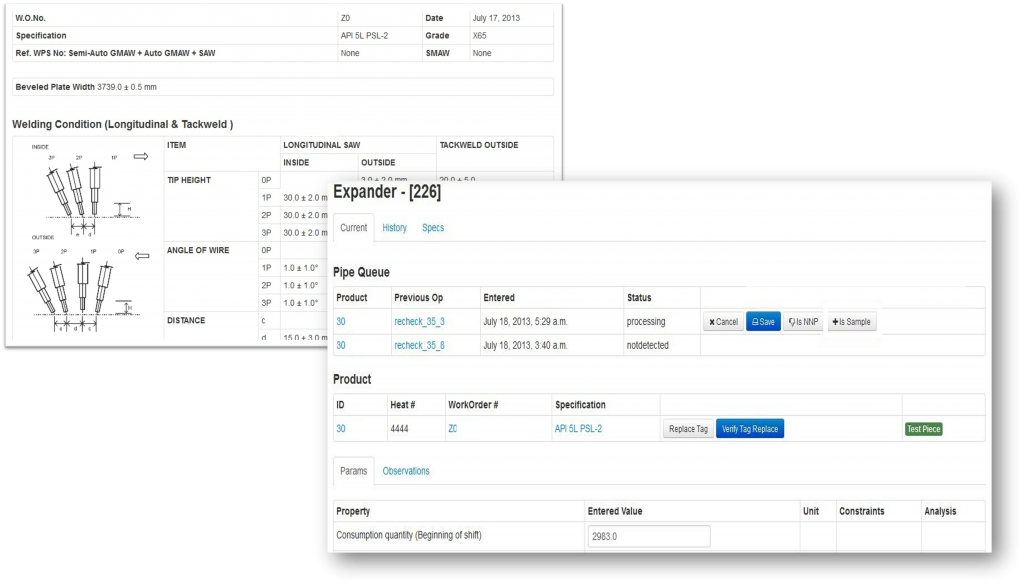

Interfaces with the machines to extract data automatically, eliminating mistakes in manual entry. Reduces the overall processing time. Provides additional data capture to be used for analytics purposes.

Solution Features

A modern solution to an old problem.

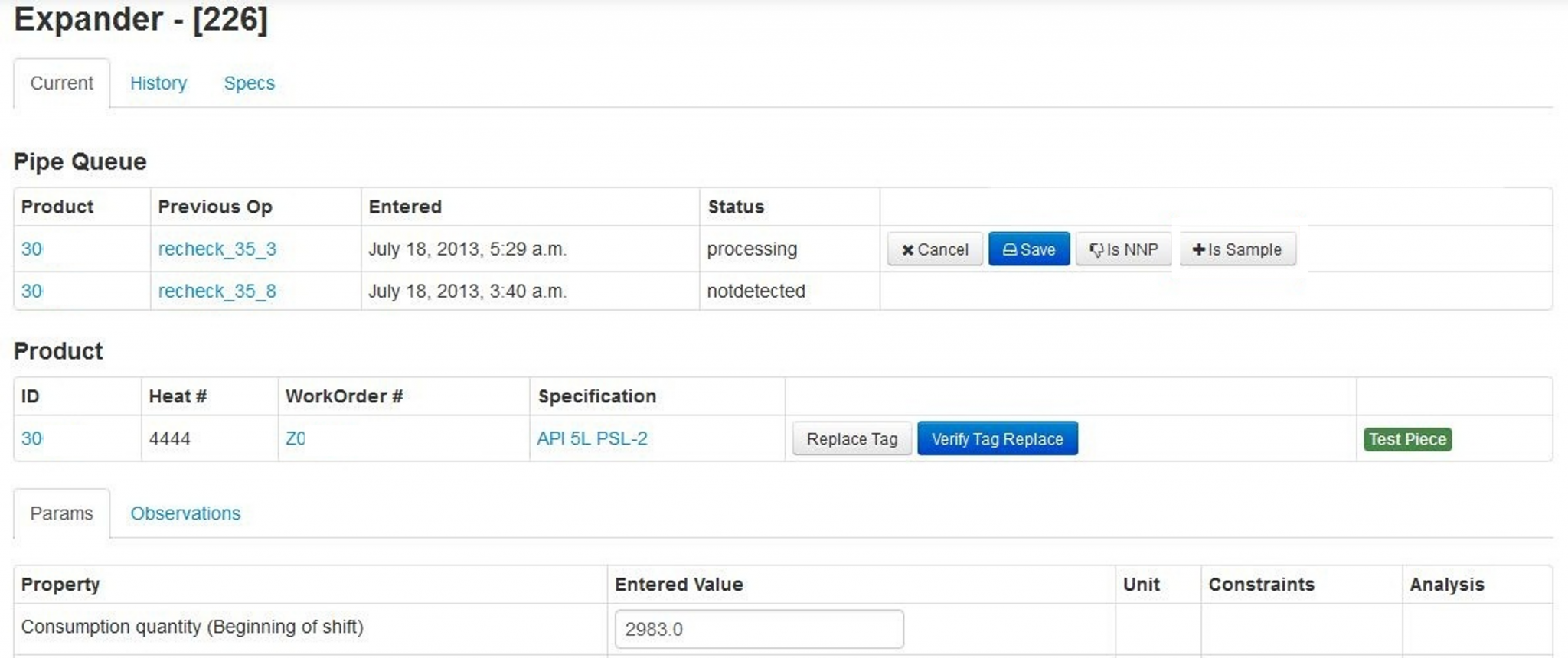

End-to-end Traceability

Provides complete visibility into the process of manufacturing from order to delivery. Comprehensive data capture to track the operations performed on the raw material as it transforms into a finished product, including but not limited to defects, inspections, repairs, non-destructive testing, operators, qualification of operators by tracking certifications and expirations, etc.

Automated Data Acquisition

Interfaces with the machines to extract data automatically, eliminating mistakes in manual entry. Reduces the overall processing time. Provides additional data capture to be used for analytics purposes.

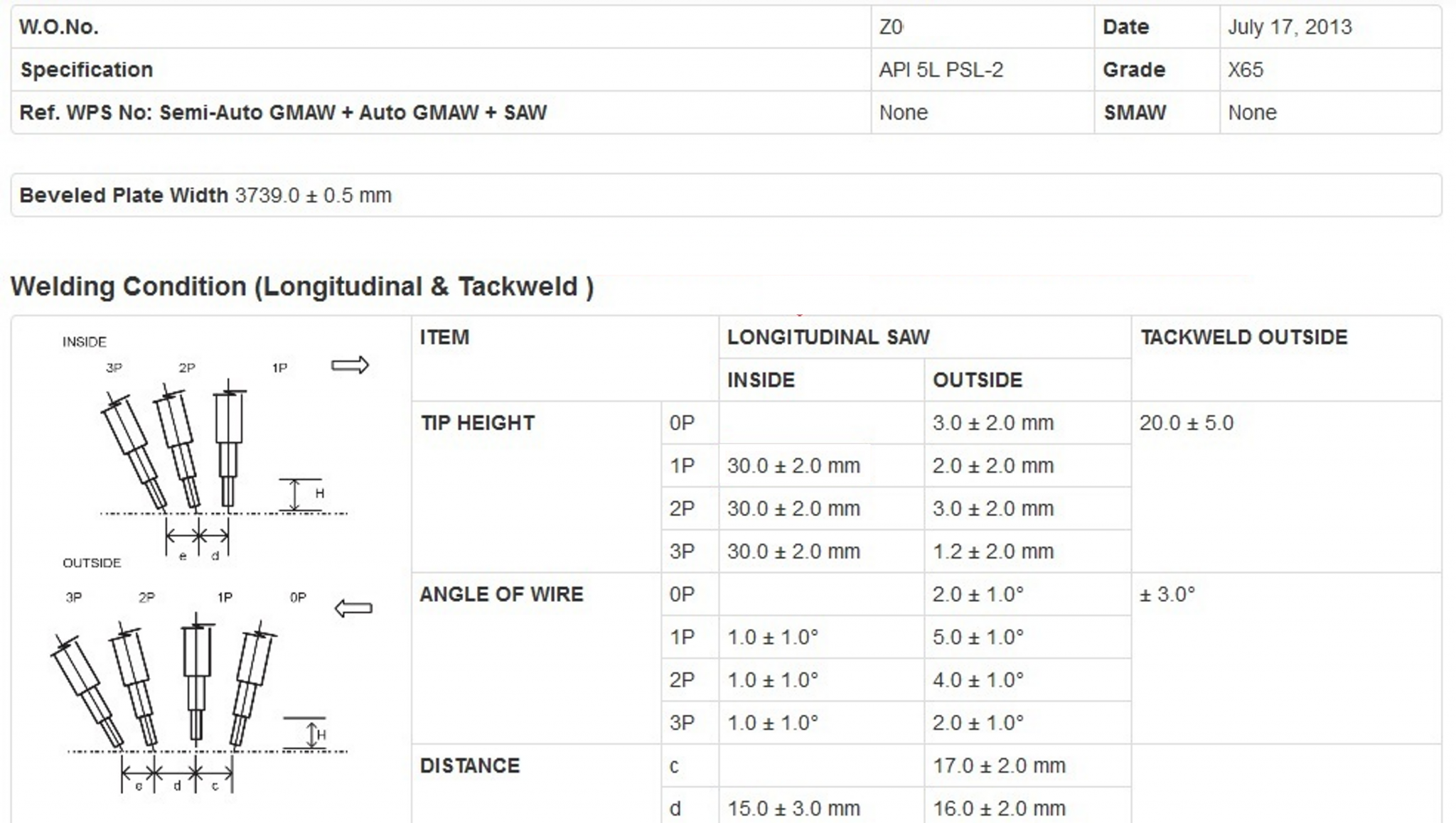

Specification Analysis

Checks in real-time the observables encoded against the specifications encoded in the work order based on the client's requirements and standard industry rules and guidelines.

Handheld

A rugged handheld unit, heavily customized, to assist the operators in the manufacturing plant by performing several operations. The handheld unit acts as a fallback for detecting where a fixed RFID-based detection is not possible due to structural constraints. Provides quick information about the product being manufactured by performing a quick scan of RFID or the barcode tag.

RFID-based Detection

An automated contact-less detection of the product as it arrives at a station for processing in the manufacturing plant.

Conditional Routing

A complex rule-based workflow engine responsible for routing the raw material through different upstream and downstream processes. Enforces repairs and inspection, when required without the operator making a manual decision.